Innovation

Innovation

Innovation for Precision Manufacturing

and the essence of innovation is to make good quality parts available at a practical price. There are various processing technologies such as metal 3D Printing, casting, forging, machining, but individual technologies alone have limitations in delivering great value.S&H will design total process to produce the optimal product, delivering differentiated value to customers. Wehas developed its capabilities by carrying out challenging tasks in various fields, ranging from the processing of new stents in the medical field to turbo pump components in the space launch vehicle engine. This spirit of challenge will serve as the foundation for S&H's sustainable success.

R&D Center

Build/operate your own Proto shop

QC functionalityIn R&D Center

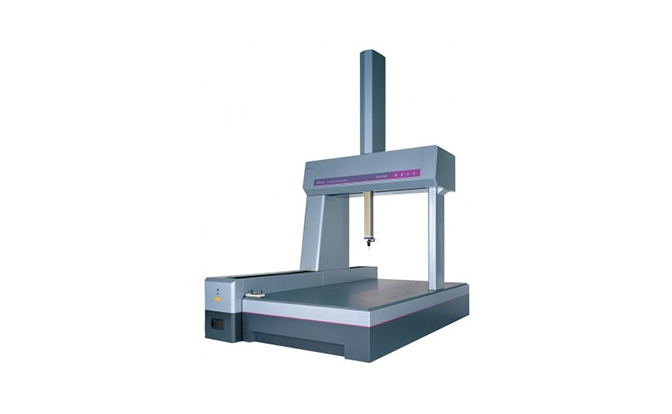

In addition to securing quality performance for developing products, the company will establish its own infrastructure that can reflect various quality considerations considering mass production.The CMM, 3D Scanner, and Metal Component Analyzer are operating to secure quality know-how.

Core Value for Development

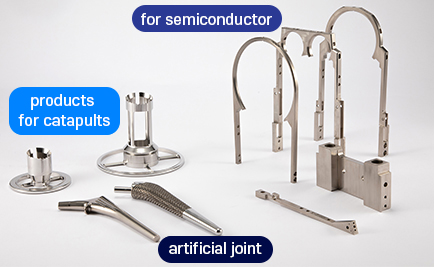

Manufacturing of Difficult-to-cut Material

[1] Titanium Product

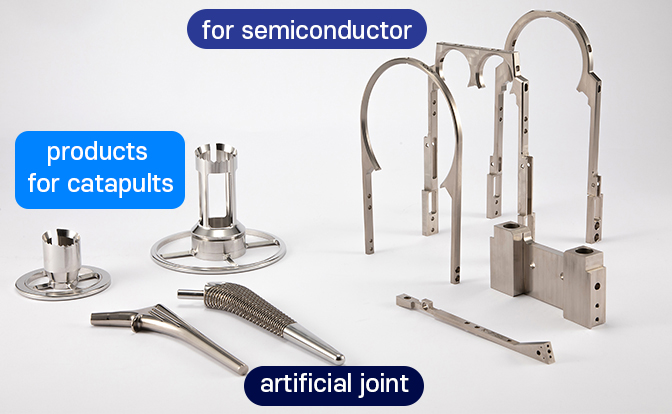

The left side of the image is a Ti material workpiece for artificial joints and hemodialysis machines.

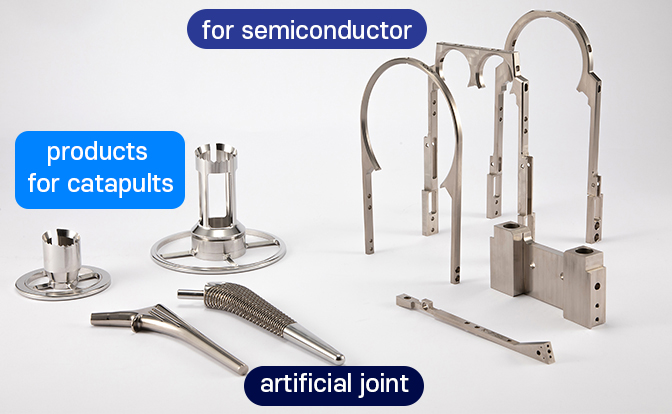

It is a product with fine shape and precision error of several microns, and on the right is a Jig-related part of the semiconductor process line.

Artificial joint parts : 170 x 50 x 18 mm

Catapultmachine parts : 110 x 110 x 90 mm

Jig. for Semiconductor Equipment : 170 x 110 x 10 mm

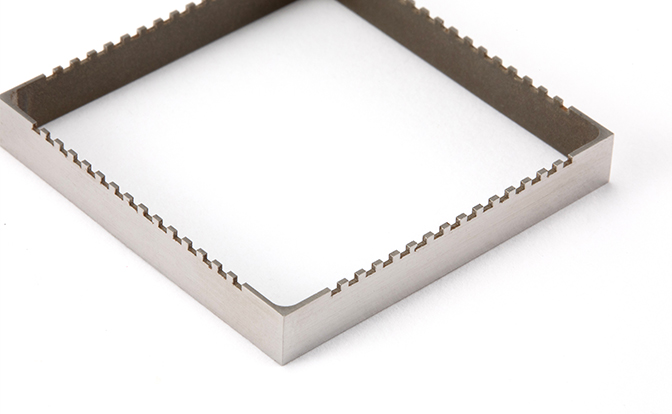

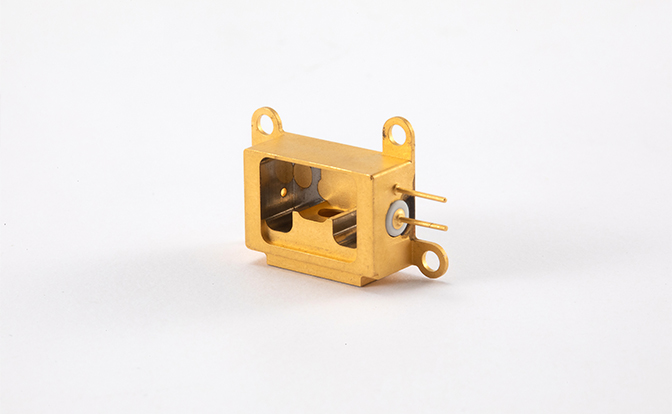

[2] Kovar(Fe-Ni-Co) Product

Kovar material, which has the same thermal expansion coefficient as the glass fiber of the optical cable as an optical communication component, is a typical rough deletion, which is a difficult product with small dimensional difficulty and low error tolerance.

Performing government Project

| Period | Type of Participation | Gov. Department | Project Name | |

|---|---|---|---|---|

| Task Start Date | End date | |||

| 2012.07.01 | 2016.06.30 | Project Member |  |

Development of Plate and Cylindrical Artificial Vessel Stents with Excellent Expansion and Flexibility |

| 2012.12.01 | 2016.11.30 | Project Member |  |

Development of High Elasticity and High Adaptability Plate Stents for the Treatment of Cerebral Aneurysm |

| 2014.06.01 | 2015.05.31 | Project Member |  |

Development of Nitinol Surface Treatment Techniques for Interventional Procedures |

| 2017.04.25 | 2020.06.30 | Project Leader |  |

Development of Turbo Pump Casing for Multi-Stage Combustion Engine |

| 2017.06.01 | 2021.12.31 | Project Member |  |

Network-based Fluid Equipment High Efficiency Technology Advanced Track |

| 2017.10.01 | 2021.12.31 | Project Member |  |

Development of High-Efficiency Fan-Shaped Membrane Cooling Hole Technology for the Application of Cooling Turbine to Airplane Gas Turbine Engine |

| 2018.08.01 | 2019.01.31 | Project Member |  |

Biomimetic Mechanical Design Based on Asymmetry, Irregularity, and Swarm Intelligence in Nature |

| 2019.10.15 | 2020.10.14 | Project Leader |  |

Development of Surface Treatment Technology for Cavity Control of High-Speed Rotating Fluid Machine |

|

|

|

|

|

|

|

|