Product

Turbocharger Parts

Turbocharger Overview

The Turbo Charger is a device that maximizes the air supply from the intake stroke of the internal combustion engine to increase engine efficiency.This increases the power output of the engine, which can be used in high performance vehicles,and reduces the size of the engine to reduce emissions.

S&H Production Parts

Compressor Wheel

The compressor wheel is a component that produces high-pressure air and is key to micrometers of dimensional management.

Since 2000, S&H has produced more than 15 million parts based on the cumulative quantity.

(Customer :  )

)

-

Start of mass-Production

since2000

-

Cumulative production

Over15 Milions

2021 Ver. -

Diameter information

20~80mm

Max Diameter up to 600mm

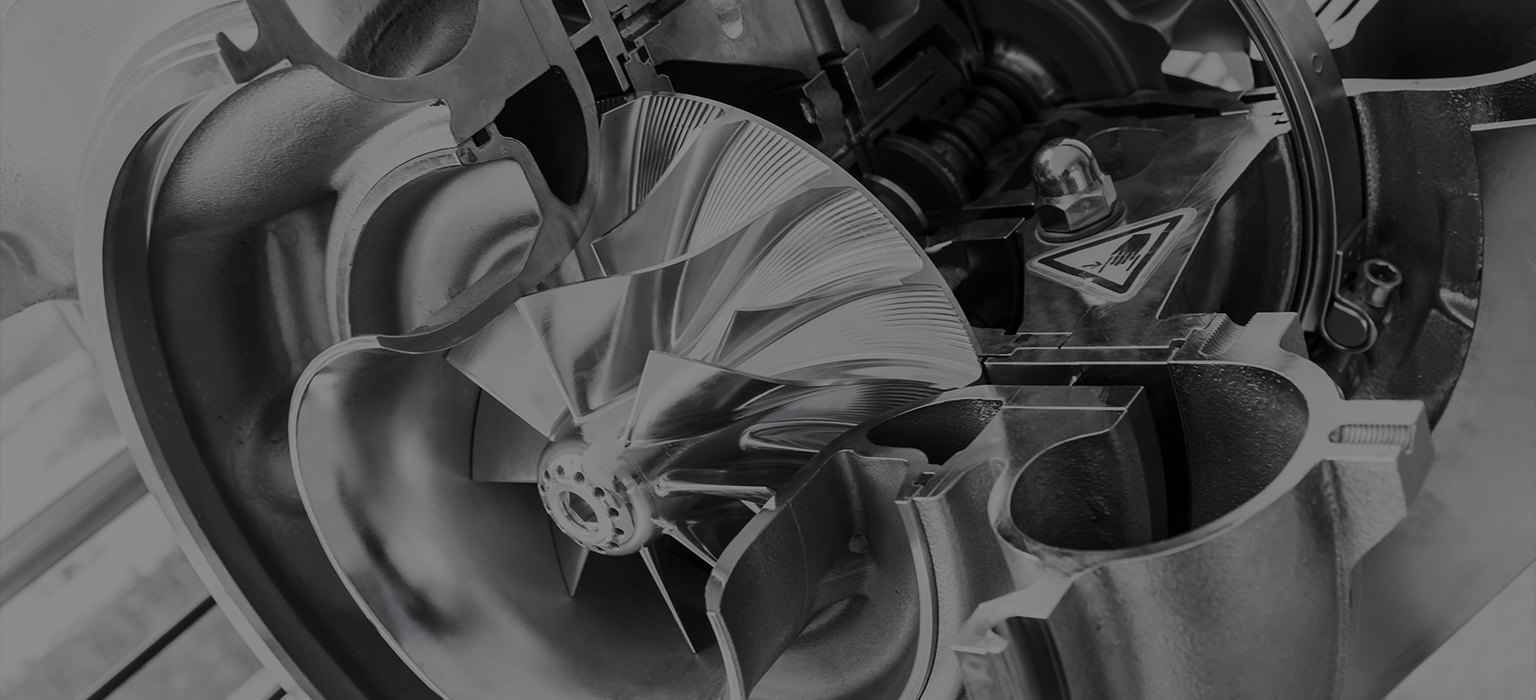

Nozzle Ring Assembly

The Nozzel Ring Assembly is a key component used in Variable Geometry Turbocharger (VGT) technology

and is an assembly with a variable Vane structure to regulate the exhaust back pressure that rotates the turbine.

This is an essential technology for improving the turbo-lag of the engine and increasing efficiency

in the low turn section.

(Customer :  )

)

-

Start of mass-Production

since2010

-

Cumulative production

Over3.5 Milions

2021 Ver. -

Production Site

Vietnam

End-User(AutoMaker)

Why us?

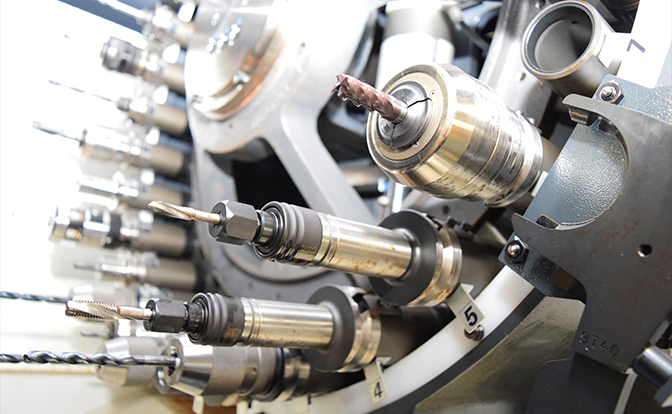

[1] Manufacturing Process Management

Process management for the production of various varieties.

Process management for the production of various varieties.

Optimization of quality stabilization time according to production conversion between varieties.

Investment for automation to increase process efficiency.

Improve quality and increase productivity with automation.

The image above is intended to help you understand.

The image above is intended to help you understand.

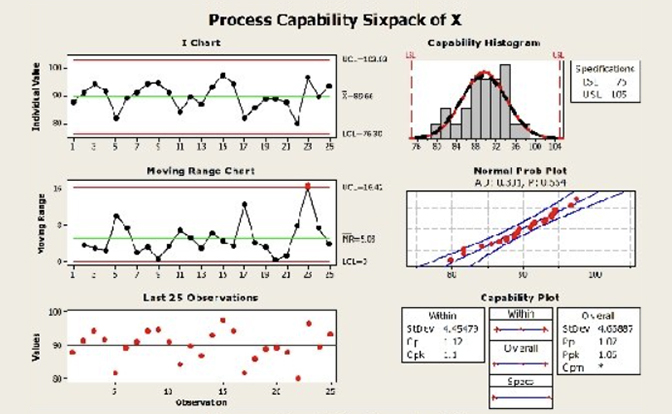

[2] Quality Assurance

Quality Center

Construction of a quality-only measurement room with a constant temperature and humidity system.

Using 6-Sigma Quality Management Techniques.

The Whole view of Quality Center

Process management

The image above is intended to help you understand.

The image above is intended to help you understand.

Automotive Quality Management System Certification

IATF 16949 (2016~)

SQ Mark (2010~)

Secure customer trust based on uniform quality control capabilities.

Maintain Single Digit PPM

WinHoneywell* Best Delivery Awards (2005)

WinHoneywell* Quality Awards (2014)

Future for Compressor Technology

Compressor Wheel is also applied to Hydrogen Fuel Cells, and S&H is collaborating with Garrett Motion on the development of compressors for hydrogen fuel cells.

The hydrogen fuel cell compressor is an essential component for increasing the reaction efficiency of hydrogen and oxygen.

for Fuel Cell Electric Vehicles Garrett’s Two-Stage compressor enables automakers to optimize electric powertrain potential by boosting hydrogen fuel cell stacks to higher pressures and flows within a downsized package that fits inside regular vehicles. Advanced bearing and electrical system designs increase performance, reduce size, weight, and noise, and help make the vision of zero-emissions vehicles a reality.