Product

Micro Jet Engine

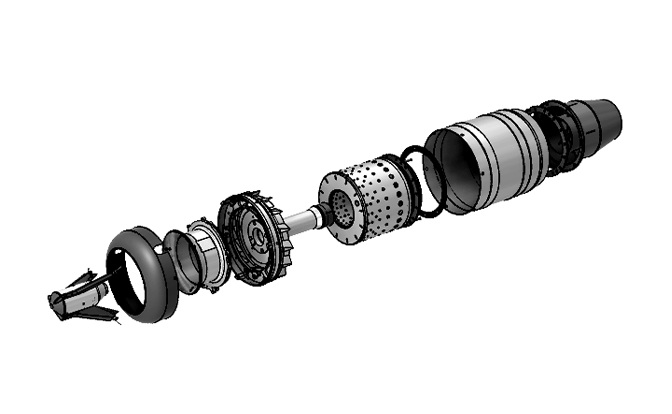

Micro Turbo Jet Engine

Based on the strengths of Turbo Machinery production, we developed Micro Turbojet Engine. With relatively excellent weight-to thrust ratio, it will play a role as a propulsion unit for special-purpose unmanned aerial vehicles. Most of the parts have developed in-house, and engine production and testing are carried out on our own. Planning to Produce engines that meet the customer's purpose in areas with thrust of 1000 N or less.

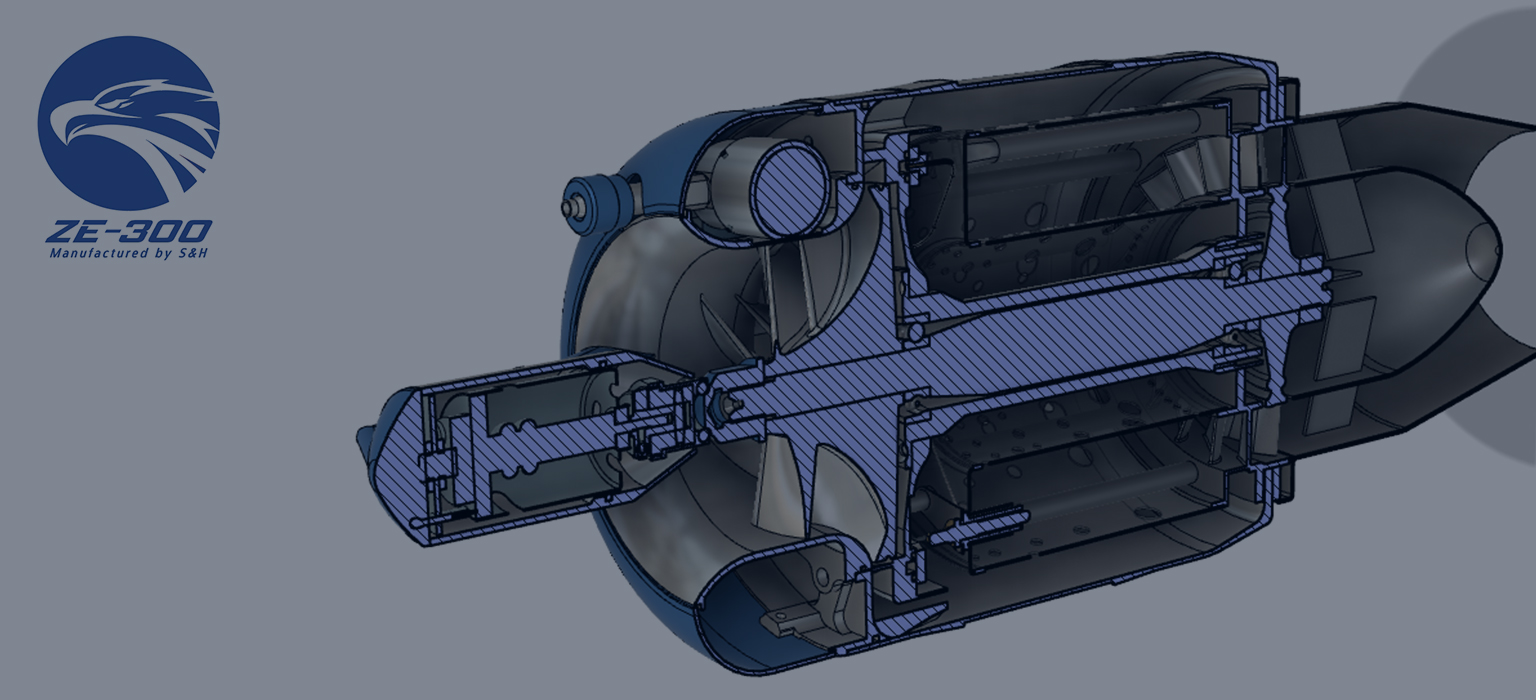

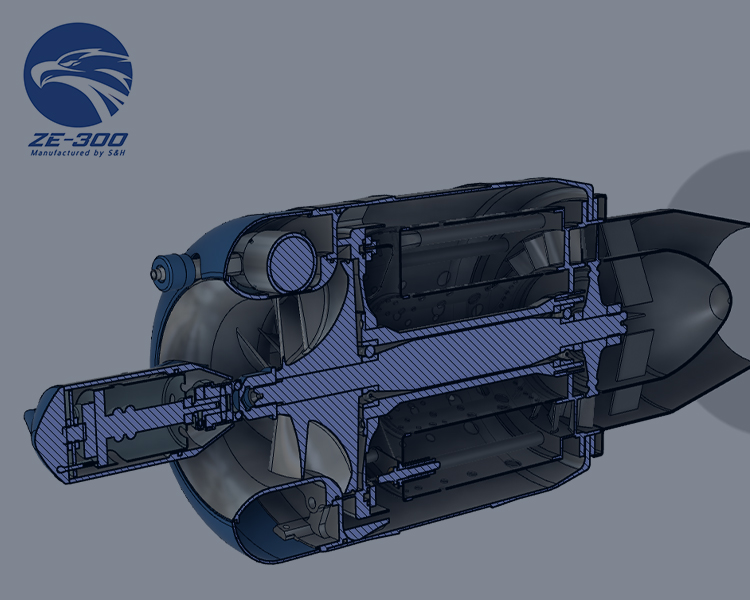

Proto type - " ZE-300 "

ZE-300

The ZE-300 engine, developed since 2020, has a Maximum thrust of 300 N at 10,500rpm, and the fuel pump, valve and ECU all have a fully integrated system inside the engine, providing the best installation convenience. In addition, it will be used in schools and research institutes with the goal of securing easy and stable start-up stability by applying Kero-Starter, completing the development of the Proto Type Model by 2023, and will make a trail as a drone propulsion system through its own test flight.

Specifications

| Name | Value |

|---|---|

| Pressure ratio | 3,55 |

| Mass flow (kg/s) | 0,5 |

| Consumption Full load (ml/miin) | 980 |

| Consumption idle (ml/min) | 179 |

| Weight[g] | 2730 |

| Dimensions of the diameter (mm) | 132 |

| Length (mm) | 380,5 |

| Batterty recommendation | |

| Carton dimensions (LxWxH; cm) | |

| Exhaust gas temperature (℃) | 480·750 |

| Idle speed (1/min) | 35000 |

| Max rpm (1/min) | 105000 |

| Thrust at idle (N) | 14 |

| Thrust @ maxRpm (N) | 300 |

| Exhaust gas velocity (km/h) | 2160 |

| Exhaust gas power output (kw) | 90 |

| SFC @ maxRpm (kg/Nh) | 0,157 |

Why us?

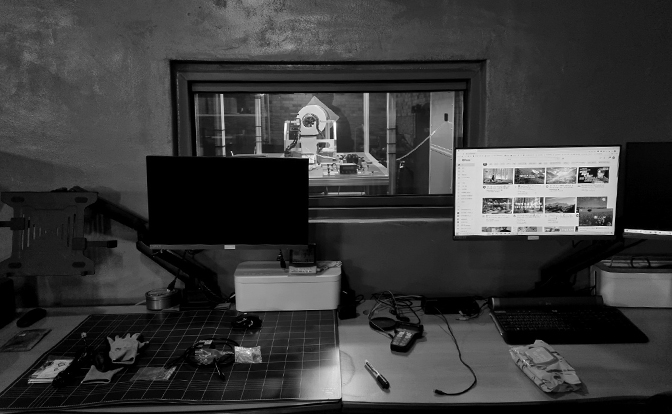

[1] Engine Test Infrastructure

Test Cell Construction

The company is equipped with a test cell dedicated to Micro Turbojet Engine. It is equipped with noise and exhaust gas treatment facilities. Test circumstances are influenced relatively little on the external environment. We are always ready to run the engine and test it throughout the year.

Engine test software and self-control logic

Control Logic has been implemented on its own until engine start and operation. We control various parameter and proceed with the optimization. In addition, a separate Data Acquisition Program was produced to measure engine characteristics and an Infra was built to guarantee engine characteristics.

[2] Major parts In-house production

Production to Assembly

Most of the components, from Jet Engine's metal processing products to Fuel Pump and Starter Motor, are localized, and the foundation for direct processing of various parts is used to produce optimized parts through Fine Tuning.Also, it can be produced stably because we directly processthe assembly and rotating body balance work.

-

Number of parts applied

75

-

Material

AL, SUS, Inconel

-

Localization rate

95%