-

Ideas to Reality,

Ideas to Reality,

We create innovation with youSolve tricky turbomachinery problems.

Goes to Innovation -

Turbocharger Parts for Automotive

Turbocharger Parts for AutomotiveAutomotive Industry

Goes to Turbocharger Parts -

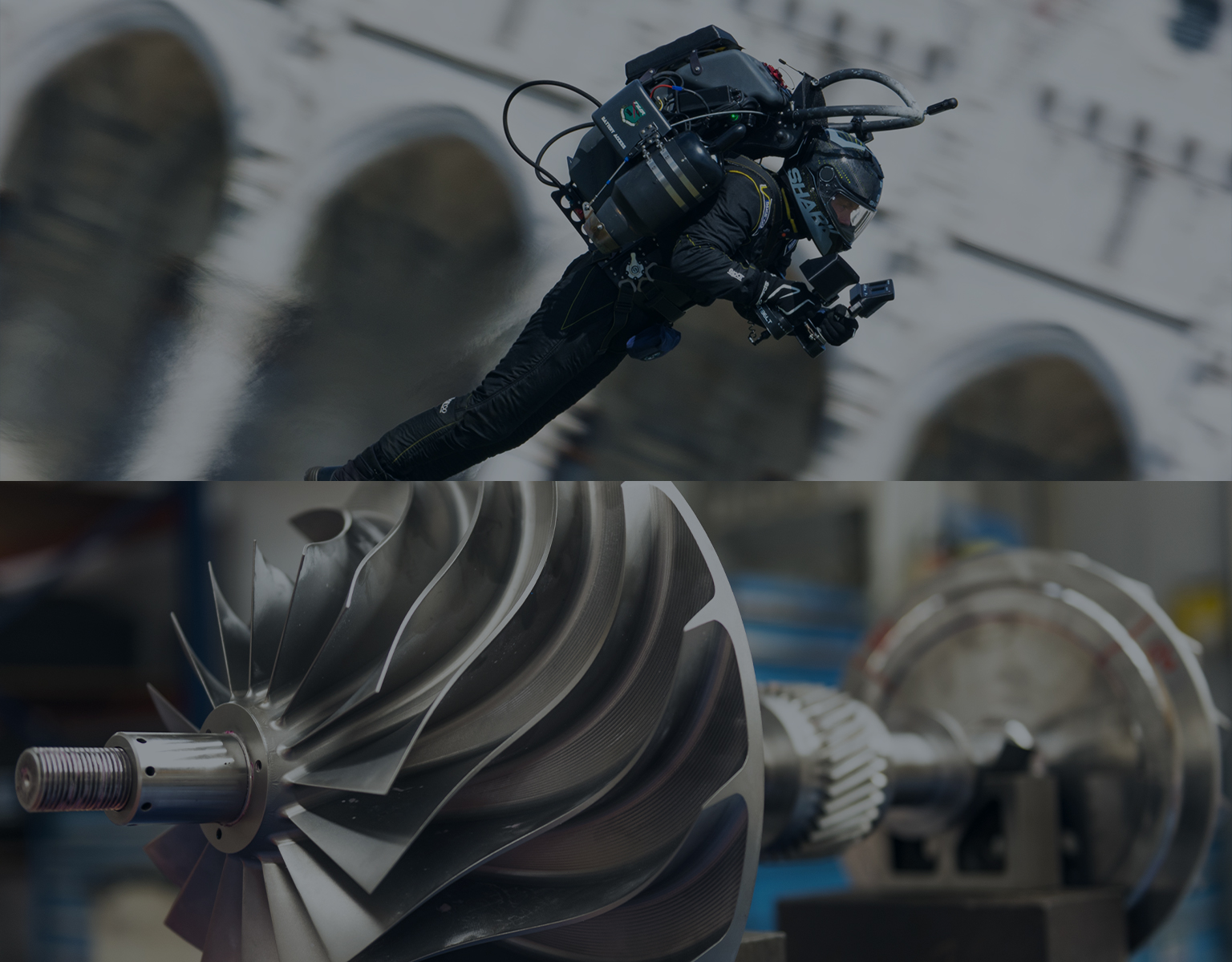

Turbopump Parts for Space Launch Vehicle

Turbopump Parts for Space Launch VehicleSpace Lauch Vehicle Industry

Goes to Turbopump for Space Lauch Vehicle Engine -

Micro Turbo Jet Engine

Micro Turbo Jet EngineHigh Speed UAV Industry

Goes to Micro Turbojet Engine

It's a world of innovation with the breakthrough in manufacturing technology, but any advanced technology has technical limitations to overcome in order to see the light of the world. There are a variety of technical challenges of manufacturing process to bring difficult ideas into reality. In terms of production technology, S&H has the strength to solve problems with various customers. From compressor parts to aviation and space vehicle engine parts, we produce them in the most economical and efficient way. We have know-how about comprehensive process design such as precision casting, machining, 3D printing, and precision inspection, and we aim to solve problems from the perspective of overall optimization.

-

Mass Production

S&H has systematically established

material, process and quality control

procedures based on over 20 years

of mass production experience.

Based on this, We had become

a supplier that can produce and

supply stable products to customers. -

R&D Center

S&H has been operating an

independent R&D organization

for more than 10 years and has the

capability to develop high-level

precision parts.

In order to efficiently respond to the

development needs of the client

company, we operate the

Proto Shop with various facilities

and equipment. -

Various Meterial

S&H has experience in processing

and developing materials that are

difficult to process and manage

quality, such as SUS, Kovar, Inconel,

and Monel alloys.

Based on the data base for materials,

we provide quality standards that

meet customer requirements. -

Investment for Future

In addition to investing in Infra

for Manufacturing, we made decision

to develop various assembly products

based on the strengths

of Turbo-Machinery.

We are constantly challenging to

provide differentiated value based

on S&H's strengths such as microjet

engine and turbopump forspace

launch vehicle.