Product

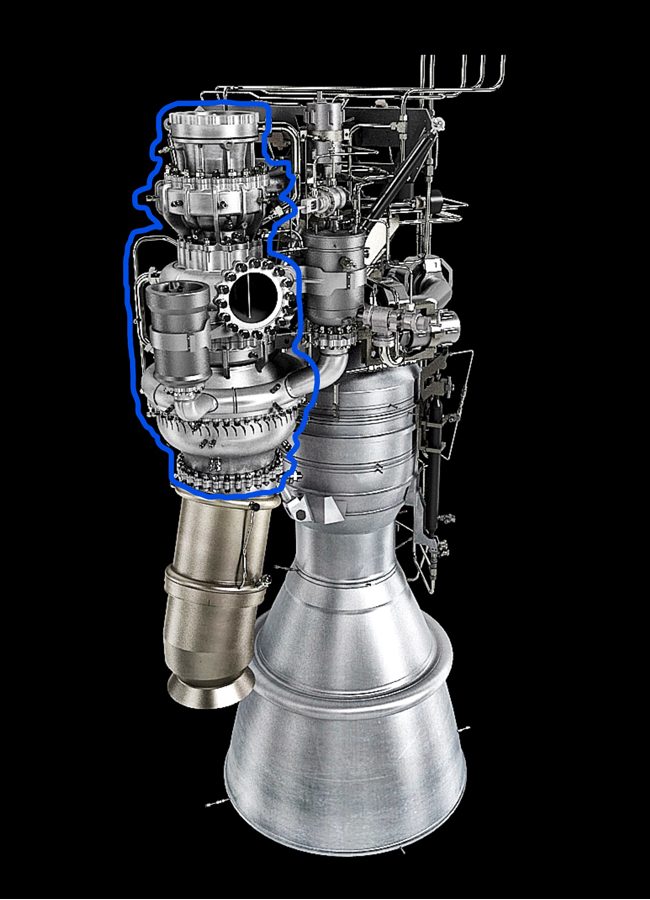

Space Launch Vehicle Engine Turbopump

Development of Turbopump Parts for space launch vehicle engine

S&H has been participating in the Korean project to develop Korean projectiles led by the Korea Aerospace Research Institute (KARI) since 2013, and has localized major components in Turbo Pump, a key technology for liquid propellant Space Launch Vehicle engines. The developed parts were mounted on a 7-ton/75-ton engine turbo pump on the KSLV-2, which was launched in October 2021. Based on the accumulated years of manufacturing technology, we are preparing to fulfill the role of private companies in the upcoming space age.

Turbo Pump with 75-ton engine

The source of the above pictures and videos is the official website of the Korea Aerospace Research Institute.

The source of the above pictures and videos is the official website of the Korea Aerospace Research Institute.

Reference Video for Turpopump Component

Combustion Test of 75-ton engine

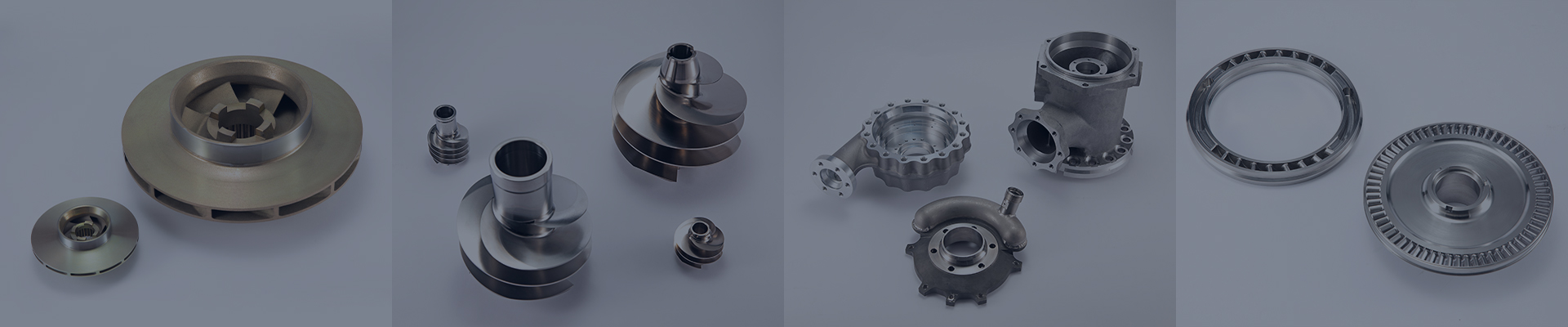

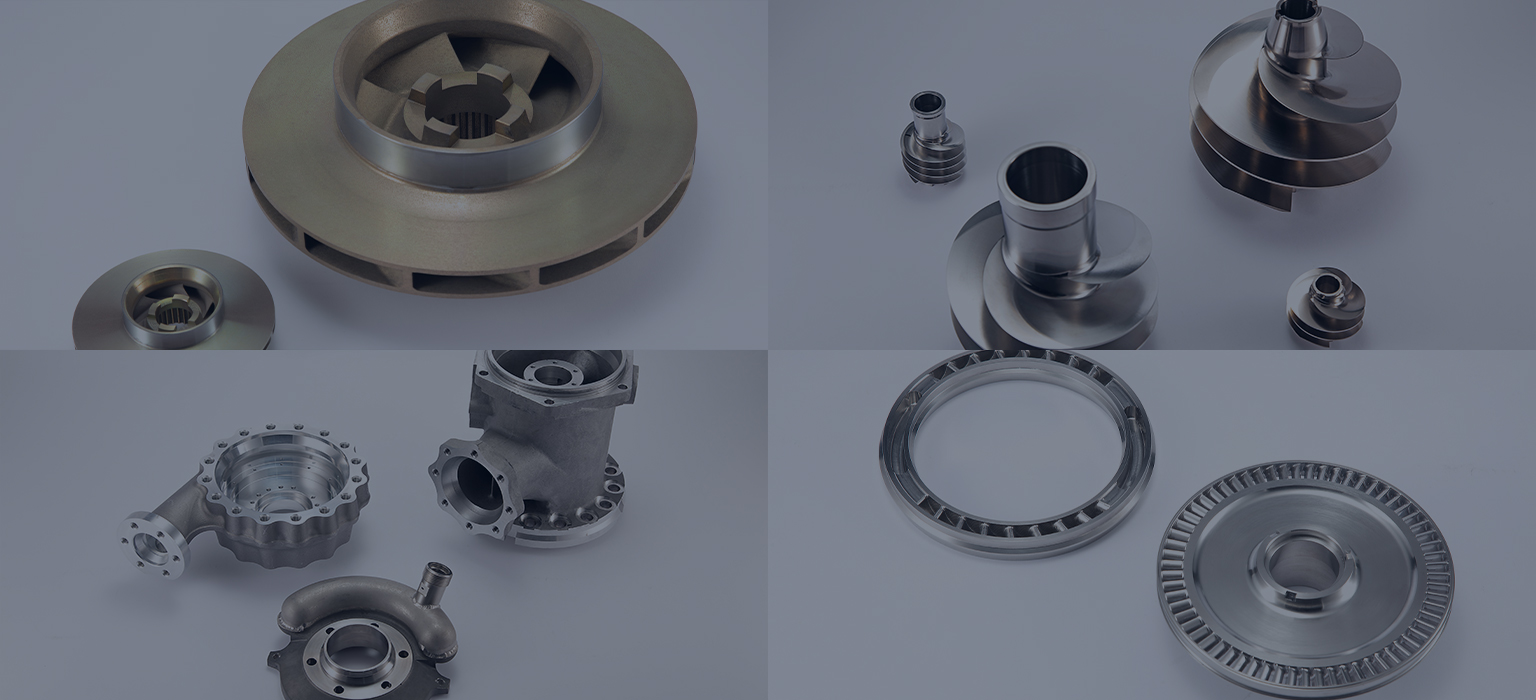

S&H Production Parts

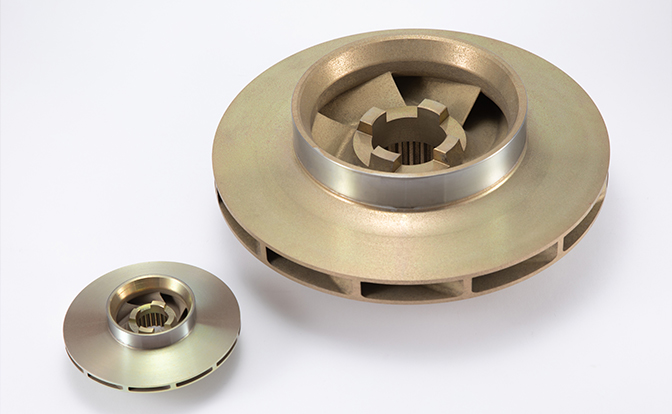

Shroud Impeller

Shroud impeller for fuel pump

.jpg)

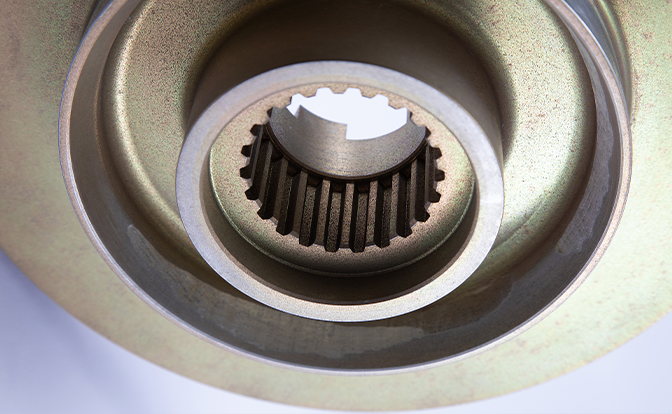

Inducer

Inducer for fuel and oxidizer pump

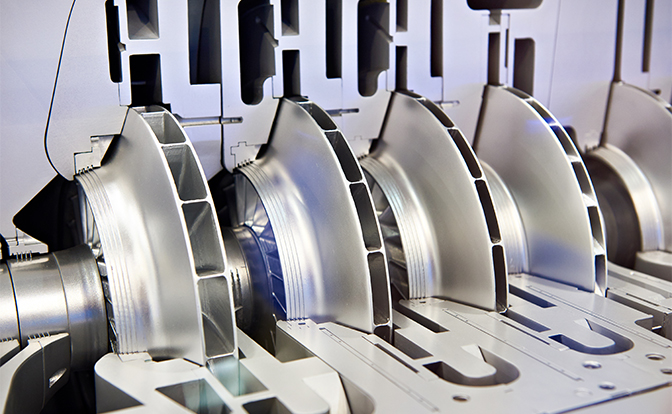

Casing

Casing for fuel pump

Why us?

Process Integration

Various processing methods are used to make parts for Space Launch Vehicle engines used in extreme environmentswith high temperature and high pressure. The shape is implemented using various processing methods such as casting, forging, and machining, and the Know-How for this is, It determines the reliability and productivity of the product. S&H acquires a lot of skills in this area and develops further.

The image above is intended to help you understand.

The image above is intended to help you understand.

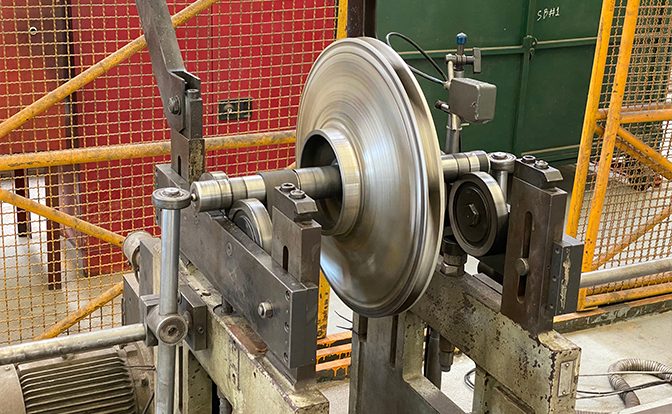

Balance & Correction for Rotor

Rotors of turbo pump rotates at high speed to make the Oxidizer and fuel under high pressure conditions. The key is the technology to detect and correct the inhomogeneous mass that occurs when the rotating body operates. S&H has a long-established rotating body balance technology and strives to further develop it.

The image above is intended to help you understand.

The image above is intended to help you understand.

Ultra-Fine Machining

The existing Casting Type parts have been implemented in a fully machine method, and we are preparing to verify them as parts. This method can dramatically reduce the cost of initial development and will have a lot of effect on development by reducing the risk of casting defects

.jpg)

.jpg)